Welcome to my blog! I thought that I would try my hand at writing about various aspects of mandolin making on a more or less monthly basis. I say 'more or less' because new submissions will largely be based on wether or not, I have the time and inspiration. New entries will be posted here with the latest one at the top so you can quickly see if there has been any activity since your last visit.

Wow! I can't beleive that I'm into my fourth year of blogging here! In order to keep things from becoming too unruly, I will begin seperating each year of blogs onto its own page. Just click on the links below in order to read my past postings.

January 1, 2025

From the time I was old enough to visit coffee houses and attend music festivals on my own, I have always greatly prefered live music over recorderd music. Although recordings are almost always technically better, in my books, there is just no substitute for experiencing a live performance. There is something about watching the musicians interact with each other and knowing that there is a potential for missed notes or "clunker" chords that makes the experience more personal, real and human.

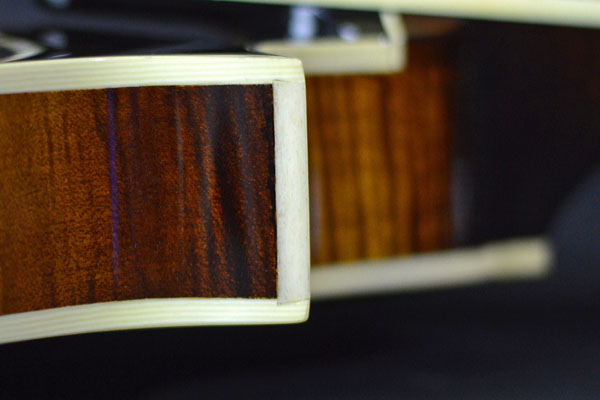

And so it is with musical instruments. Although modern technology has largely replaced human skill and craftsmanship with greater speed and precision, it comes at the cost of the unique, one-of-a-kind aspect of a truly handcrafted item. Predictable, repeatable, uniformity, even at a high level, just doesn't speak to me as much as a skillfully, individually crafted, musical instrument with its evidence of hand working and unique personality does.

Don't get me wrong, I see no reason why a good or even great sounding instrument couldn't be made using highly automated machinery if the programmer was highly experienced and the right materials were chosen. It just doesn't have as much meaning to me just as a live performance is a deeper experience than a recording.

Up to now, I have resisted investing in a CNC carver. Carving hard maple by hand takes it's toll on an aging body but by the Lord's grace, I am still able to do it at this point and I hope to be able to continue carving by hand well into the future. That said, it is possible that at some point, I will have no choice but to stop building mandolins or, invest in a CNC carving machine.

The trouble with that is, once the machine is in the shop and you have invested time learning how to program it, the temptation would be great to say, 'why not use it to make body blocks?' 'How about carving necks and cutting inlays?' Soon you are on the path to carbon copy widgets. It's ye olde slippery slope as they say.

I'm blessed, at this time, to not have to think about that and for the time being at least, can create my one-of-a-kind instruments in all of their perfect imperfection.

Thanks for reading,

Oliver

March 31, 2021

While the idea of a mandolin specifically designed for jazz had been in my mind for many years and that I thought I had spotted a niche within a niche, I had no idea how successful this project would actually become. When one of the leading exponents of the jazz mandolin, Don Steirnberg began using one of my jazz models on a regular basis, it was an extremely gratifying highlight of my 40 years plus as an instrument maker. I actually had Don in mind while designing my "J" models! Well today, I am announcing another huge highlight in the career of this luthier with the news that the matchless virtuoso of the mandolin (and one-time student of Don Steirnberg), Aaron Weinstein has also become an endorser of my jazz mandolin line!

I don't know exactly how or when I became aware of Aaron Weinstein but while watching his Instagram videos, his talent is immediately palpable. A virtuoso on the violin and mandolin and a heck of a funny guy as well. It's no wonder the great Tony Bennet called him "the Groucho of the violin." At some point we started following each other on Instagram and before long we were emailing each other. The discussions usually revolved around things like 'what would be the ultimate sound of a jazz mandolin' or the need to be able to plug in when surrounded by other loud amplified instruments. The latter then led to 'What would the ultimate jazz magnetic pick-up for mandolin sound like?'

During this time, I was in discussions with Mike (Smitty) Smith of MJS Pickups on designing a floating humbucker custom sized and voiced for a mandolin. Smitty proved to be extremely knowledgeable on all aspects of pickup design and gave me a crash course in pickup fundamentals. After detailed discussions on the specific needs of a mandolin pickup and some prototypes I had made, Smitty delivered the first two working pickups that he had custom fabricated from the ground up! I could barely believe the power and warm tone that came out of such a compact design. Smitty nailed it!

Meanwhile, sometime in late 2019, I started working on a mandolin for Aaron on the side, whenever I could steal a couple of hours. There were many times that I had to put the project aside and catch up with the orders on my waiting list. Aaron was amazingly patient through it all.

Finally, the big day did arrive. The finished "Yorkville" model with floating humbucker arrived at Aaron's New York Apartment. I saw by the tracking on DHL's website that it had arrived and Aaron confirmed this with an email. Since the weather was still somewhat cold at that time, I advised Aaron to let the mandolin warm up slowly in his home before opening it. So he did and told me that the suspense was killing him. He literally had to leave to go for a walk as he could not put the mandolin out of his mind otherwise.

Meanwhile, I was also waiting in great anticipation of what Aaron's first impressions would be. I would receive no response that whole day nor the day after. I was beginning to make up scenarios in my head from 'maybe he can't put it down long enough to email me' to another scenario inspired by my, usually very supportive wife's comment of, "you know, it's much harder to let someone down than give praise." Then, late in the third day, I received a personal call from Aaron and to my great relief, he told me that he really loved the mandolin and we had great chat like two old friends. This was the first time we ever talked to each other over the phone rather than by email.

Here is a quote from an email Aaron sent me after having spent some time with his new Yorkville. "This mandolin plays like a dream! It has the most extraordinarily warm, round acoustic tone that is virtually unchanged when plugged in. It's the perfect Jazz mandolin sound, the sound that I've been searching for. This instrument is a game changer!"

I'd like to say that if you are a mandolin player and are not aware of Aaron Weinstein you would really do yourself a favour by checking out his website, YouTube channel and Instagram page. Whatever your style, you will be inspired by his incredible command of his instrument as well as being thoroughly entertained by his wit and dry humor.

I'll leave you with some photos of Aarons new axe #13820. A custom Yorkville model.

Here's another video on Peghead Nation where Aaron Weinstein demonstrates his new Yorkville jazz model in more depth.

For more on the optional custom made floating humbucker, scroll down to my May 1s, 2020 post.

As always, thanks for reading.

Oliver

July 13, 2020

Back in 2016, my wife and I set up a trade show booth at the IBMA's World of Bluegrass in Raleigh, North Carolina. One thing that impressed us while there, was the number of young people who have taken up bluegrass as a serious pursuit. It made us feel great to see that this traditional art form is presently in very good hands. The level of playing from these young folks was nothing short of astonishing!

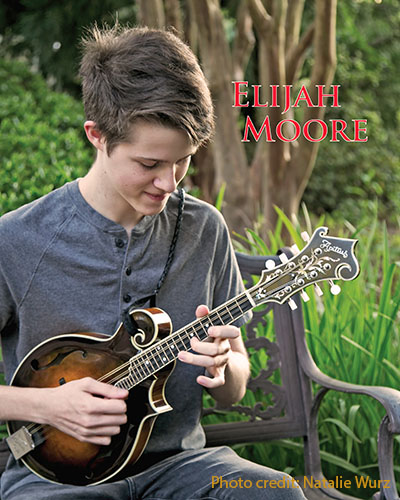

One young man in particular caught my attention. He and his father stopped by our booth to try out the mandolins. I remember getting a vibe that these were great people. You know, polite, humble and honest. I came to know that the young man's name was Elijah Moore and his father's name was Eric. Well, Elijah sat down to pick some, I believe he was just 12 at the time, and boy what a player he was. I just got the feeling that I was watching someone with a real gift.

After having a nice chat for a while, they moved on to see more of the show but I could see that Elijah really liked my mandolins. Of course, though, it's not easy for a 12-year-old to afford a top level mandolin!

My wife and I went back to Raleigh with our booth the following year in 2017. We were very happy to see Elijah and his dad there again and again, Elijah picked up one of the mandolins that I had there and really impressed us with the progress in his playing. We had another great chat and I believe that I gave him some promotional merch that we had with us to take home as a souvenir. 'just something about Elijah and his dad that I liked. 'good people.

Well that was that and we went home and haven't been able to attend the IBMA trade show since. A combination of logistics and having no spare mandolins around for a show just made it unfeasible. It is truly a great show and we do hope to return someday.

A 12 year old Elijah Moore at the Apitius Mandolins booth

in 2016.

As fate would have it, a couple of months back a mandolin of mine became available to me again. As I pondered what to do with this mandolin, my wife suggested, 'why don't you give it to an up and coming mandolinist?' I immediately thought of Elijah and how he seemed to love my mandolins. So........, I have made an investment in the future and signed my youngest ever endorser of Apitius Mandolins! I have a feeling that the world will be hearing a lot more of this young man in the coming years!

Here's his bio.

Elijah is a 16 year old, award winning mandolin player from North Carolina. He started playing when he was 10 years old and is influenced by Alan Bibey, as well as his teacher, Ralph McGee. Elijah has won several contests to date, including first place, youth mandolin at the 2018 Old Fiddler Convention in Galax, VA. Elijah presently plays in the 2019 Telluride Band Contest Finalist Band, "One Fret Over". He is also a member of the Americana trio, "The Nomads".

Welcome aboard Elijah!

I'll leave you with a recent photo of Elijah with his Classic Model, Apitius Mandolin.

Until next time, thanks for reading and stay vigilant,

Oliver

May 1, 2020,

Hello everyone. It's been awhile since I've made a new blog post. Things have been very busy here, in a good way. I have lots of orders that I'm working my way through but I just had to share some exiting news!

The concept for my jazz model mandolins had been fermenting in my head for a long time before they ever became a reality. When I finally got around to actually producing them, I was very pleased with the instant success of those models. It seems my instincts were right, that there would be a demand for such a model and they have been very well received. Up until now however, there has still been one missing ingredient that I had wanted to add ever since the jazz models were just a gleam in my eye.

From the very start, I had envisioned an option for a floating humbucker for those players who wished to plug in whether for more volume or an expanded tonal pallet or both. The problem was, I knew almost nothing about pickups at all and I wanted to wait until I could offer something specifically made for my jazz mandolins rather than just mounting something that wasn't ideal.

I have always been a strictly acoustic instrument maker. I have nothing against electric instruments, it just wasn't my area of expertise. It's my nature to try and get really good at one thing as opposed to being "OK" it a number of things and that hasn't changed. My number one priority remains building the finest sounding and playing instruments that I can. I am continuously seeking ways to refine my instruments to be among the very best available. The great thing about a floating humbucker is that I can still make an instrument with a primary focus on having a great acoustic sound with the added option of plugging in.

Of course I had a steep learning curve ahead of me and so I began researching all about pickups. How they work, what the different tonal characteristics of various configurations are and so on. A couple of years ago, I had a chance encounter with a custom pickup maker named Mike "Smitty" Smith at an exotic wood dealer in Burlington, Ontario. I presented Smitty with the idea of a custom humbucker sized and voiced for the mandolin and I could immediately tell that this man knew his way around a pickup. We had a long conversation that day and many more over the phone in which Smitty gave me an intense crash course in pickup construction and wiring.

Budget restrictions and fullfilling current orders slowed down the process of turning my idea into reality. As luck would have it, just as I was getting ready to commission a prototype pickup from Smitty, who's business by the way, is called MJS Custom Pickups, I received a fortuitous request from a customer for a floating humbucker. I was also contacted by the fabulous jazz mandolin master, Aaron Weinstein who was also looking for a mandolin with a floating humbucker. Aaron and I went on to exchange many emails over the next months discussing in great detail the elements that would make for a truly high level, jazz specific, mandolin pickup. I am so grateful for the opportunity to have the input and opinions of such a high level jazz musician. If you haven't heard of Aaron Weinstein, a visit to his website and YouTube channel will be a revelation!

Well, after years in the making, the first ever, Apitius "Club Jazz" with a custom made floating humbucker will be shipped off to the above mentioned customer and the great Aaron Weinstein is in the queue to receive number 2. So without further adieu, as they say, wait, I think that last part was some more adieu Oh! now I just made even more adieu! Shut up. Here's some pics.

The first Apitius mandolin with a custom floating humbucker!

A custom "Club Jazz" serial #13420

Close up showing thumb-wheel tone and volume controls at pickguard edge.

I have to say, I'm very happy with the end result. It took many hours of R&D along with the generous input of Smitty at MJS Custom Pickups and jazz musician Aaron Weinstein. The power output is amazing for such a compact design. The pickup is a mere 9mm thick, including the genuine rosewood cover! So, when I get caught up on current orders and reopen my waiting list, my jazz model mandolins will now include the option of a custom made, floating humbucker!

Thanks for reading,

stay vigilant,

Oliver

October 26, 2019

I've been meaning to post a blog about a very special customer from Belgium. This past August, Jefferson Louvat, a leading proponent of the mandolin in Europe flew in to visit my shop and to take delivery of the mandolin that I had custom made for him.

A resident of Brussels, Jefferson has traveled to perform at many legendary rooms and events including the Grand Ole Opry, The Station Inn, the IBMA as well as various festivals throughout the U.S. and most of Europe. In 2010 he signed with prestigious German record label, Acoustic Music Records, and released an album A Walk With You with excellent French guitarist Thierry Massoubre. In 2011 Jefferson, his brother Steve on banjo/guitar and Jazz bassist Michel Vrydag released their first Louvat Bros self-entitled album. The Louvat Bros. trio won the 2012 Liz Meyer award at the EWOB (European World of Bluegrass) rewarding the European’s most innovative band in Bluegrass music. Jefferson left The Louvat Bros in 2016 and now performs with his duo, Szabadság.

I was thrilled to have Jefferson contact me about building him a mandolin. Of the number of very specific design elements that he requested, the most notable for me was that the instrument was to be left handed. It was to be the first time that I had ever made a left handed mandolin in over 40 years of making instruments. (I have since received an order from another left handed customer) I knew that it would present some challenges and I welcomed those. I did not realize just how many little details would require special attention. The build really kept me on my toes as I dared not make a cut without thinking twice about whether I needed to do things differently. In the end, I was very pleased with the result. Though I could not play the mandolin myself, it sure sounded great from the listener's side when Jefferson played the first proper tune on it.

I'm not exactly sure how Jefferson got to know about my mandolins. I assume that it was from an American player touring Europe. The line in my logo "World Renowned Quality" while a throwback to the style of ad copy used in the 1920s, does actually have a basis in truth. Over the years I have gotten several orders from Japan, one in England and of course many from all over the U.S. and Canada. Now I can proudly add Belgium to the list.

The added thrill this time was a visit from the over seas customer to pick up his mandolin! Jefferson and his lovely partner, Ariane Cohen-Adad, made the trip expressly to take delivery and have a tour of the shop. They also lined up a few gigs in Quebec and Ontario to help fund the trip and to make the most of their time in Canada. Knowing that, among other things, Belgium is known for it's fine beers, I arranged a little tour of my area that took us to the scenic town of Creemore. The town of Creemore is home to one of the best, if not the best, craft breweries in Ontario called Creemore Springs. They adhere to the Bavarian Purity Act of 1516 which stipulates the use of only four ingredients, barley, hops, water and yeast. One of their great advantages is the quality of water they use. It comes from a spring on the Niagara Escarpment and gives the beer a fresh, crisp taste. I think Jefferson approved!

Later that night, my wife Jody and I went to see Jefferson and Ariane play their first gig with his brand new Apitius mandolin. It was at a nice little club in Toronto called The Burdock where they shared the bill with another mandolin virtuoso, Andrew Collins and his trio. The duo of Jefferson and Ariane go by the name Szabadság and play an eclectic mix of Dawg, Newgrass, Klezmer and traditional Bulgarian music. They are both talented musicians and put on a very entertaining concert. If you ever have the opportunity to catch one of their shows, I highly recommend you do.

I'll leave you with a couple of photos of Jefferson's visit.

Here is Jefferson playing his mandolin for the first time!

Ariane, Jefferson, myself and Jody taken pre-show at The Burdock in Toronto.

Jefferson's Mandolin

Below is a video that Jefferson recorded for me after he returned to Belgium.

Sam Bush's "The Old North Woods" played by Jefferson Louvat from Apitius Mandolins on Vimeo.

As always, thanks for reading,

Oliver

October 7, 2019

'Want to be a more interesting person? Attract members of the opposite sex? Be the envy of all the hep cats? A real humdinger? Well now you can!

"I used to clap on 1 and 3 but now, I snap on 2 and 4 since I discovered quality merchandise from Apitius Mandolins." So what are you waiting for? Get out of that puddle your sitting in and march yourself down to the Apitius Mandolins, Boutique & Emporium. Get hep to the latest craze!

Well, it's very unusual for me to post two blog entries in one month let alone in one week but I'm very exited about a new-to-me website that a recent customer of mine turned me on to. It's called Redbubble and it does the job of providing, selling and shipping artist "merch".

I have at times, had t-shirts and other promotional materials on offer to my customers. It was never a "profit center" for me, nor did I ever intend it to be. It was just to promote my brand and create some good will. It did become a bit of a drain on my time and resources, so much so, that I put the idea on the back burner in recent times. Not only did I not have much of a mark up on the items that I had on offer, but when I got a request for something, I would have to package it up, go into town to the post office, fill out a customs form and pay the shipping. That cost me a good chunk of the day as well. When you're a one person operation, it's astounding how much time is spent on things other than making mandolins. That's why I was so glad to have been told about Redbubble.

Redbubble is an internet business that allows someone like me to offer an array of promotional items without having to pay for and store inventory or even deal with the sale of these items. With t-shirts for example, I had to guess at the total number of shirts that I would require and how many in each size. Inevitably, I would guess wrong and be left with shirts that no-one wanted and customers for whom I didn't have the correct size. Redbubble promises to print one-offs on demand so that "I" am never out of stock. They sell directly to the customer and then send me a commission. I get to choose the amount of commission that I get. Since I don't expect to make a huge amount of merchandise sales and am in it mainly for the promotional value and to provide a service for my customers, I have set the the commissions very low to keep things as affordable as possible.

I just spent the weekend setting up my new "store" on Redbubble and so I do not have any experience, at this time, as to the quality of their service or goods. They have been around awhile and from the descriptions and reviews, seem to have quality products. I have ordered one of almost everything that I have on offer at my store just so I can see first hand what my customers are getting. If I am dissatisfied with the service or quality of the goods when they arrive, I will of course, close up the shop. I do not want my customers receiving inferior goods. At this point, I have no reason to believe that the quality of the items on offer will be less than expected. If any of you purchase something from my Redbubble store, feel free to email me about your experience.

I have set up a separate merchandise page on this website that can be accessed from the "Pricing" page or by following this link. My Redbubble store can be visited here.

While the Redbubble website is very well done, I found that it could be more clear and user friendly in some aspects. For example, I had a little bit of difficulty finding all of the products that I had put on offer. (I'm not the most tech savvy) If you visit my store and want see all of the offerings, first click on one of the designs shown on my account page and then click on the link that says "view this design on #s of products" as shown in the screen shot below.

Below is a sampling of some of the merchandise that I have on offer so far. I plan on adding more in the future so you might want to check it out from time to time.

Classic Tees

Women's Hoodies

Men's Hoodies

Women's Tees

Mugs

Travel Mugs

Water Bottles

Coasters

Stickers

Tote Bag

Clock

Posters

As always, thanks for reading,

Oliver

Update Oct. 22, 2019: To date, I have received a t-shirt, a mug, a set of coasters and some stickers. and I can tell you that the quality was very good on all of the items. The shirt was a Gilden brand heavy cotton (100%) with great print quality.

October 3, 2019

There's not a whole lot to share this month so I thought I'd tell you about my new apron. Many luthiers, the majority I'd say, wear an apron while working in the shop. Woodworking can be very dusty as well as messy when working with stains and varnishes. In addition, the wear and tear of the contact between ones body and the various work surfaces can be hard on your regular clothes.

The usual aprons are made of denim and perform reasonably well. I have worn a denim apron for my entire 40+ years as an instrument maker, going through a half dozen or so over the years. For many years now, I have wanted a suitable leather apron as leather functions much better in several significant ways but I have always balked at the cost. It is false economy of course as leather will far outlast denim in the long run while functioning better as well. Aside from longevity, leather will not get saturated with sawdust and allow the dust to reach your clothes. The dust just slides off. It offers better protection from spilled liquids. It also offers better protection from sharp objects and tools and lets not forget, it looks great!

I have been searching the internet lately for an apron that would do all of the things that I want an apron to do. Although I found many really great leather aprons on offer, all of the ones that I found had at least one drawback and that was the use of metal. Whether it be buckles or rivets, I do not want any metal parts potentially coming into contact with a mandolin in progress as I work on it. That could result in a very problematic ding. I was starting to give up on the idea when I had a thought. The apron that I want would be rather simple to make for someone with some leather working tools and know-how and so I made up a drawing of what I wanted and took it down to my local shoe repair shop. After a bit of explaining, I was satisfied that the cobbler understood what I was after and commissioned the work.

The next week I took delivery of what I expect may be the last apron that I will ever need. I also felt good about supporting an independent business. As I write this, I have only worn the apron a couple-three times and so far, it's great! The leather has just the right suppleness and is very comfortable to wear. Below is a photo of me showing off my new acquisition that was taken earlier today. It was worth the 40 year wait!

Me with my new leather apron by "Perfect Shoe Repair" in Orangeville ON.

As always, thanks for reading,

Oliver

August 19, 2019

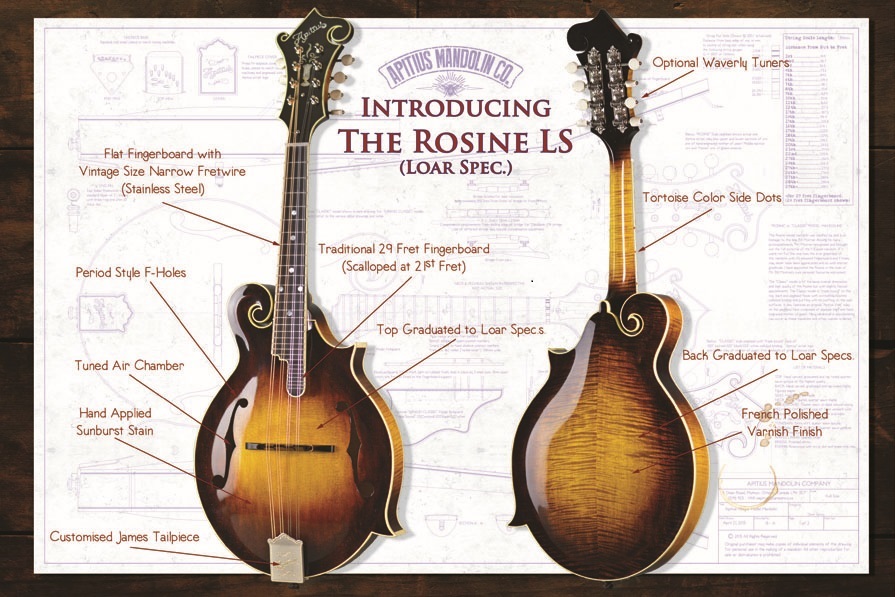

I'm very exited to announce a whole new voicing option for Apitius mandolins! I have always thought of the traditional Loar sound as being akin to a good upright piano whereas the Apitius sound is like a good grand piano. The Loar has great overall balance with emphasis on the mid-range, fewer overtones and less sustain with a directness and quick response. The 'Apitius Sound' is more complex with a richness of overtones and plenty of sustain. That said, You would not necessarily choose a grand piano to play ragtime or barrel-house boogie. Likewise, if you want to play primarily hard driving, traditional Monroe style bluegrass, the 'Apitius Sound' may not be for you. My sound, while quite capable of playing bluegrass, especially contemporary styles, is much more versatile. Many players today, play a variety of styles including classical, jazz, Dawg and Scotts/Irish. For those players, my original Apitius sound would be the way to go, but for those who want to capture as closely as possible that raw, in your face Monroe style, my new "LS" designation is for you.

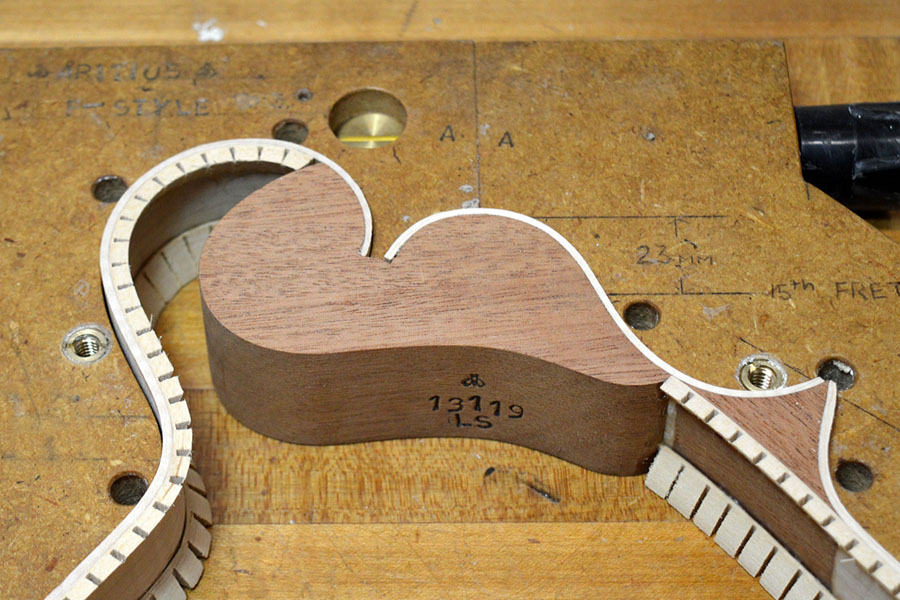

The LS voicing can be applied to any of my A or F models which would then get the LS designation. For example, a Vanguard model would become a "Vanguard LS" a Rosine would become a "Rosine LS" and so on.

The new "LS" voicing is the result of painstaking research and attention to detail. After carefully studying the graduations of six individual Loar signed F-5s, I meticulously crunched the numbers to come up with a graduation pattern that I believe, represents what Lloyd Loar was going for. While the originals were somewhat uneven in their graduations, I take great pains to ensure a consistency and evenness in my mandolins while staying true to the original measurements.

The LS designation doesn't end with the graduations of the top and back plate. Although my mandolins since 2015, have had many details of the original F-5s, the LS goes even further to include a traditional shaped neck block, traditionally shaped and placed tone bars, Loar style F-holes and triangular, basswood kerfed linings. Just to be as thorough as possible, the first ever "LS" has a 29 fret, flat fingerboard (as opposed to my usual 24fret conical fretboard) with narrow vintage sized frets of stainless steel. My philosophy with the LS is basically, if you want it to sound like a Loar signed mandolin, build it to Loar era specs., entirely!

Of course my F-style mandolins up to this point have already included many Loar era details that are often overlooked by other makes. Things such as a multi-ply headstock veneer with dyed pearwood overlay, tortoise colored side markers, dovetailed points on 'top bound' models, hand applied sunburst stain and a thin, French polished varnish finish.

My intention for the first ever LS model, a Rosine LS #13119, was to send it down to Carter Vintage Guitars in Nashville and have my good friend, Forrest O'Connor, record one of those demos of it. This was going to be my big launch!

Things took an unexpected turn however. After playing the LS, Forrest fell in love at first hearing and has now acquired the mandolin for himself! This is some of what he had to say in our correspondence.

"............ I did get to spend some time playing it today though, and it only took about 10 or 15 seconds to realize that you accomplished your goal with this one! To be honest, it may be my favorite directly Loar-inspired mandolin I've ever played. I would say that my Grand Classic has a little more depth (which makes sense given the design differences), but there are other things about the Rosine LS that are just inspiring. Whether it's because of the design or because you just keep getting even better with each mandolin, I feel like it may have the edge in projection, acceleration, and perhaps even midrange magic. It actually reminds me of Crusher, Grisman's Loar (the best Loar I've ever played)."

Of course I couldn't be more thrilled, to hear this from a very accomplished, high level musician who grew up in Nashville and has gotten to play many Lloyd Loar signed mandolins over the years. Perhaps I can get Forrest to record a sound demo of the mandolin in the near future so that I can post it here.

Dec. 11, 2019 Here' a great demo that Forrest sent me! In it, he talks a liitle about his new Rosine LS and gives it a spin on a few tunes.

For those of you still reading, here are a couple of photo examples of some of the differences between my own version of the F-5 and the new LS models.

In the above photo, you can see the difference between the Apitius developed rim on the right and the LS rim on the left. Notice that the LS has a traditionally shaped neck block and triangular basswood linings. Virtually every aspect of the LS designation is true to the original design and quality.

Instead of my unique tone bar profiles and F-holes, the Loar Spec. utilizes traditionally shaped F-holes and tone bars. (Apitius on the left, LS on the right.) Among other things, this results in a main air resonance one half step higher than on my original mandolins.

For a brief description of the different voicings available on Apitius mandolins, please visit the new voicings page here.

Thanks for reading,

Oliver

July 29, 2019

From time to time, I get asked about the bee in my logo. What is its significance if any? Today, I think I'll give a brief explanation of why I use the bee as my symbol.

I am a second generation Canadian. My parents emigrated here from Germany in the mid 1950s. I know Apitius doesn't sound like a German name and it isn't, although my folks are thoroughly German, going back for centuries. The name is a hold over from when the Roman Empire occupied the land that is now Germany. The Romans were expelled by 476 AD but some surnames survived. The spelling that my ancestors use may quite possibly be a mis-spelling of the name Apicius as the two would be pronounced similarly in German. If so, I could be a very distant cousin of Marcus Gavius Apicius, a first century Roman nobleman and gastronome, credited with writing the first book of recipes, De Re Coquinaria or De Re Culinaria.

What does this have to do with the bee? Well, in Latin, the word for bee is api or apis which is the root of Api-tius. So Apitius can be taken to mean bee like or, as a bee. When I learned of this, I thought I would adopt the bee as my symbol. So there you have it, in case you have ever wondered about my logo.

Pronunciation Help

"Apitius"......... uh - PIT - tee - us (Much like the last four syllables of "Strad ivarius")

Until next time, thanks for reading,

Oliver

P.S. I'm expecting to make a surprise announcement later in August. Bee sure and check back in a few weeks.

July 5, 2019

I'd like to take a moment this month to give thanks to Lloyd. Lloyd has been with me for over 29 years now and has given me dependable service above and beyond the call of duty. Lloyd is my UPS delivery driver. He first started showing up at my door to receive and deliver packages in 1990 when I was living in a 100 year old, log farmhouse in Adjala Township, Ontario.

My workshop was in a construction site, field office trailer that I had converted to a wood-shop complete with spray-booth. Unfortunately for me, the owners of the house had decided to sell and the new owners wanted to move in and so, I had to move out. Times were tough for me in those years and I had to hall the trailer workshop up to my parents place for a couple of years while I got back on my feet. Eventually, I was able to purchase a home that was about 15 miles from the old log house. To my great and wonderful surprise, Lloyd showed up at my door when I arranged to ship out a mandolin! It turned out that UPS had given Lloyd a new route that just happened to include my location.

When I first moved in, I got a job as a school bus driver to help supplement my income. Lloyd had gotten to know my schedule and would adjust his route to accommodate me, showing up between my twice daily runs. I remember one time when we happened to cross paths on a local side road, me in my bus and him in his UPS truck. He flagged me down and explained that he hadn't been able to get by my place before I had gone out and was now on his way home. I told him that was OK and that he could bring the package of supplies around tomorrow, but Lloyd insisted that my place was not far out of his way back home and that he would bring the package 'round so that I could take delivery.

That is the kind of personal service that is so lacking in most businesses these days and is so much appreciated when you encounter it. I can honestly say that Lloyd has been the major reason that I have stuck with UPS for all these years. I understand that he will be retiring in a couple of years. I wish him many years of happy, healthy retirement and he will be missed.

Lloyd, my UPS driver of 29 years picking up a brand new mandolin to be shipped to an awaiting customer.

June 1st, 2019

This month is a rather special month for me. For many years I carried around, in my head, my concept for a jazz specific mandolin. I finally got to make it a reality a couple of years ago with my first "Yorkville" model which sold very quickly. That was a clue that I was on to something that resonated with jazz style players. ("resonated" see what I did there) The first real legitimization for me came when jazz master, Don Stiernberg, took notice and became a fan and endorser of my J-models.

Well this month the icing was put on the cake when I received in the mail, an advanced copy of Downbeat Magazine which included a review of one of my Yorkville models written by Keith Baumann. The fact that the oldest and best known jazz magazine in the world recognized my J-models as serious jazz instruments give me a deep feeling of accomplishment.

The issue with the review will be out in July 2019 but I have permission to share the article with my audience now. I'd like to thank the folks at Downbeat and especially Keith Baumann for being so great to work with. Below is an image of the cover. Click on the image to see the whole article.

Thanks for reading,

Oliver

May 2, 2019

This month I'd like to continue with some more of the refinements I have developed over the years to create the "Apitius Sound". Specifically this month, I will discuss my unique tone bar design as well as my approach to the f-holes.

Below is pictured the traditional placement and profiles of the tone bars. This arrangement is commonly known as "parallel" tone bars although they are not technically parallel. The term is used more to differentiate this placement from the next most popular design, the X-brace. The off center and asymmetrical placement is meant to control the fundamental mode of vibration of the top plate in order to promote a more balanced sound.

Traditional Tone Bar Placement and Profiles

The profiles that I developed take this idea one step further. Not only are the locations of Apitius tone bars asymmetrical but their profiles are as well. The bass side bar is shaped much like a violin bass bar as it is high in the middle tapering to almost nothing towards the perimeter of the soundboard. This is done with the intent to encourage the fundamental mode of the plate for a full deep bass response. The treble side bar on the other hand, is scalloped down to a very low height right under the bridge position. This is done to promote the higher modes of vibration for bell like highs. Together, these tone bars help to create the full spectrum richness that is the Apitius Sound.

The Unique Profile of Apitius Tone Bars

The f-holes on my mandolins are also unique to Apitius mandolins. Smaller in area and more elegant than the traditional shape, they are used to tune the main air resonance of the body for a beautifully balanced tone. F-holes act much like the single tone control knobs found on early hi-fi sets. On those sets, turning the knob one way will increase bass response while diminishing the trebles. Turning the knob the other direction will increase treble response at the expense of the bass. The key is finding the sweet spot. After much experimentation, I have found that for my mandolins, an air cavity resonance of about C#4 produces the best overall balance.

Next time, I will talk about my patent pending graduation pattern for the top plate.

As always, thanks for reading,

Oliver

April 7, 2019

I'd like to talk about some of the things that differentiate the Apitius Sound from other mandolins. What is the Apitius Sound? Though it is difficult at best, to describe a sound, I think that a good analogy, that other high level musicians have agreed with, is that the traditional F-5 from the 1920s can be likened to a very good upright piano while the Apitius is like a Busendorfer grand piano. That is, the Apitius has more sustain and richness of tone while the 20s F-5 has a simpler yet well balanced tone. The Apitius Sound is no accident. Over the 40 plus years that I have been pursuing this craft, I have developed what I believe to be refinements in the carved top mandolin sound.

As most luthiers will tell you, good sound does not rely on one or two major elements. Rather, it is the sum of many little refinements and details that alone would not make a significant difference, but together produce a result larger than the sum of their parts. In today's blog I'd like to describe one of the refinements (actually several refinements to one element) that set my mandolins apart from others.

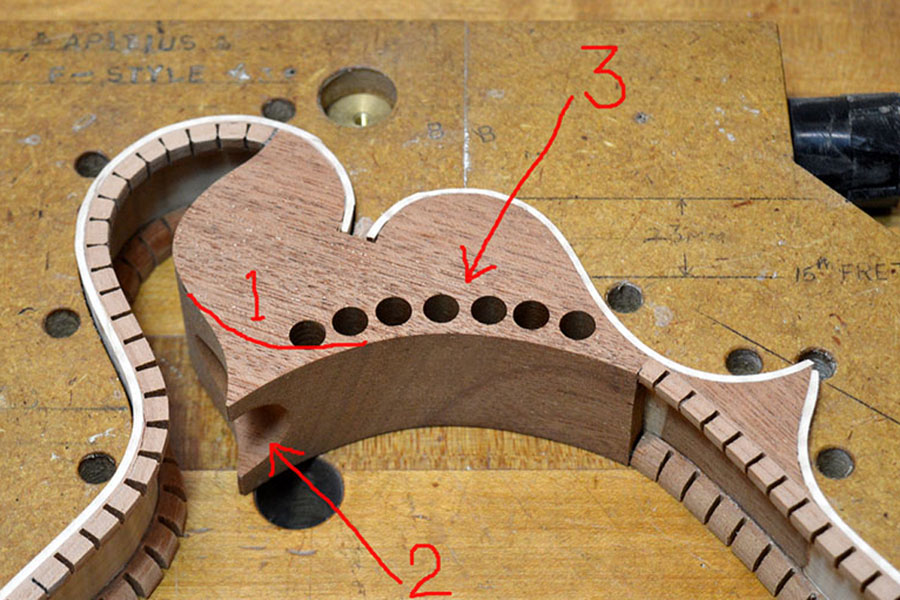

The neck of the instrument must have a strong and solid anchor point on the body of the mandolin. To this end, a block of genuine mahogany is glued to the inside of the rim with its main function being to provide a solid anchor point for the neck. On an F-style instrument, the block also acts as the inside part of the scroll and a gluing surface for the top. It is this last function that this blog will focus on.

In the first photo below, is a neck block similar to the blocks used on the original F5s. You can see how the maple side cleverly splices into the block to form the "button" area of the scroll. You may also notice that there is a significant gap in the area between the block and the maple side to the left. If you imagine the functional, vibrating area of the top as a being round or somewhat oval in shape, you can see that it is well supported all around its perimeter except in that area to the left of the neck block. This is potentially a hindrance to getting maximum power and efficiency from the top plate. An analogy would be the frame of a loudspeaker. A good rigid frame is essential in getting the most power and least distortion from the cone. (the top functions much like a speaker cone)

Traditional Neck Block

To remedy this situation, I have altered the design of the neck block to offer a more solid support for the top plate. Below you can see the design of an Apitius neck block. There is an extension added in the area marked as #1 to lesson the size of the unsupported area of the top. This gives the top a slightly more rigid attachment to the rim. The red line indicates the approximate shape of the traditional block.

In order to reduce the extra weight caused by this design change and retain much of the air volume, the area is hollowed out as much as possible as indicated by the #2 and holes are drilled for even more weight reduction. I have weighed both the traditional shape and the Apitius design and have found the Apitius to be the same weight to a gram lighter than the old style which both weigh in at around 74 grams. The Apitius block, while no heavier, offers a more rigid attachment for the functioning part of the top plate.

Apitius Neck Block

This is just one of many innovative refinements that contribute to the Apitius Sound. I hope to describe some of the others in future blogs. Until then........

Thanks for reading,

Oliver

March 7, 2019

This month, I'm going to let Forrest O'Connor do the talking by reposting this very recent video that he and partner Kate Lee, posted to their YouTube channel. Kate and Forrest post regularily, every week on Wednesdays as part of their ongoing series, "Born in Nashville".

In this episode, Forrest talks about his Apitius, Custom Grand Classic and ends with a dazzling version of "Whiskey Before Breakfast". The episode was recorded in Kate and Forrest's home studio in Nashville Tennessee.

February 3, 2019

It's been a long time since my last blog entry. I've been extra busy in the past few months with some exiting developements that I hope to be able to share with you in the not so distant future. In the meantime, I thought that it would be good to explain some of the many subtle details that I've been including in my mandolins of late.

As I state on my home page, my objective in building F-style mandolins is to recreate the outward aesthetics of the Loar period mandolins while incorporating the refinements to the graduations and tone bar profiles that I have developed over my 40 years in the business. Refinements that have resulted in "the Apitius sound". I believe that those original mandolins were true masterpieces of design and visual aesthetics. I have tried to verify who it was that was responsible for that design, which began with the redesigning of the F2, F3 and F4 in around 1910 when Orville's original "3 point" design was refined to the now familiar 2 point version, but none of the experts that I have spoken with can say with any certainty, who that was. Someone at Gibson, and it wasn't Lloyd Loar, had an extraordinary eye for aesthetic beauty. Some speculate that it was general manager, Guy Hart but there is no hard evidence for this. From the initial major redesign around 1910, the F models were tweaked continuously over the next decade with the culmination coming with the introduction of the F-5 "Master Model" in 1923. It just boggles the mind how they got so many things right. A feat like this is unlikely to occur in today's world where ease of production dictates design parameters instead of a more pure and free artistic expression. The F-5 was not designed with production efficiency as the driving concern rather, an instrument of the highest quality, to surpass all others seems to have been the aim. My aim is to capture these details and recreate the level of hand made quality that made these instruments come to be iconic.

Just to give the reader an idea of the details that I am talking about, let my give a partial list of these details that are often not present in other modern, F5 style mandolins;

Tapered Dovetail Neck Joint. Because of the compound curves and angles this joint requires on an F style instrument, many manufactures use alternate methods of neck attachment but nothing has surpassed the traditional tapered dovetail for strength, vibrational conduciveness and reversibility.

Off Center Neck Joint. If you examine an original F5 closely, (or F2s & F4s) you will notice that the neck is attached to the body a little to the left of center. While there is some disagreement among experts whether this was intentional, it is present on nearly all examples and in my opinion contributes to the overall aesthetic by 1.) tucking the scroll in closer to the fingerboard and 2.) creating the illusion that the inner line of the scroll transitions and blends smoothly with the line of the neck. It is interesting to note that in order to achieve this off center attachment, the neck must be angled in such a way as to have the centerline of the fingerboard intersect the centerline of the top precisely at the bridge position.

Off center neck joint. (note subtle curve of fingerboard extension)

Ebony Fingerboard Support. To my knowledge, early Loar signed F5s had fingerboard supports of maple. At some point this was changed to ebony and was probably done for structural reasons rather than aesthetics. None the less, I have also switched from using maple to using ebony. I have not had any problems with the maple supports but I have come to like the look of the ebony for this purpose.

Ebony fingerboard extension support.

Dovetailed Point Protectors. The original F5, when 'topbound', had its point protectors dovetailed into the binding. The fitting was done by hand and made for a more secure attachment of the points which by necessity are glued to the end grain of the sides. I have carried on this tradition which many modern makers omit.

Point protectors are dovetailed into the binding on 'topbound' models.

Tortoise Colored Side Dots. Another detail much overlooked is the use of tortoise colored side dots on the fingerboard. It's a small detail but it gives that extra bit of refinement befitting a high quality instrument.

Tortoise colored side dots.

5-Ply headstock veneer. Most modern makers use a headplate of solid wood, typically ebony. The original F5s actually had a head plate made of a special 5-ply sandwich of hardwood veneers with alternating grain direction for strength and stability. The outer visible layer was of black dyed pear wood. Using a solid veneer is actually easier in terms of production but does not offer the greater strength and stability. Using hot hide glue, I glue up my own sandwich of 4 maple veneers plus an outer veneer of dyed pearwood. The back of the peghead receives a single layer of dyed pear wood mostly as a decorative element, as was done on the Loar signed instruments.

Gluing up a 5-ply sandwich of maple and dyed pear wood.

The plies are visible in the truss rod pocket.

The back of the peghead gets one ply of dyed pear wood carved into a 'widow's peak'.

Black Varnish Applied to Headstock Face. In addition to using black dyed pear wood on the face of the peghead, the original F5s had their peghead faces painted with a black varnish. The pearl shell inlays would then be scraped clean. This extra procedure results in inlays that have maximum contrast to the background substrate. Since no one knows the exact formulation of this black varnish, I use a proprietary formula to 'paint it black' and then scrape it from the inlays once it has dried. Again, very few are including this extra detail in their mandolins.

A proprietary black varnish is applied to the peghead face.

When dry, the varnish is scraped from the inlays.

Angle-cut and Tapered Headstock. While we're focused on headstock details, let's not forget that the original F5 mandolins had pegheads that were both angle-cut and tapered from end to end. Angle-cut refers to the angle of the sides of the pehead relative to the face. Instead of the side edges being square to the face, as might be expected, the originals were cut square to the fingerboard plane and therefore 13° to the longitudinal plane of the peghead. This results in a peghead with gently twisting dimensions which is rather pleasing to the eye. In addition to being angl-cut, the pegheads were also tapered slightly in thickness from end to end. Again, rather pleasing to the eye and serving no other function. In fact, a tapered headstock creates complications when installing today's precision tuning machines but these are the kind of small details and extra effort that make for a truly great and inspirational instrument.

Angle-cut and tapered headstock.

Hand Applied Sunburst Stain. While the majority of modern makers use spray techniques to achieve the familiar shaded top of the arched top mandolin, the original F5s had their stain hand applied directly to the wood. While spraying very quickly produces an even coloration, and is therefore the method of choice for most production shops, it does not fully bring out the full character of the wood. Applying the stain by hand using a cloth applicator requires much more skill and time but when done well, results in a finish that brings out the individual character of the wood, helping to make each instrument truly unique. While spray methods produce a look that can be said to be technically more perfect, true art does not depend on technical perfection but rather aesthetic perfection that speaks to the human soul. After all, a photo of a woman sitting by a lake is technically more perfect than a painting of one yet the Mona Lisa still captivates us in profound ways.

Appying stain by hand.

Hand applied stain and French polished spirit varnish.

Well I think you get the idea. Apitius instruments are made with an attention to detail far exceding the majority. Striving to produce only the best is what motivates me and the wonderful feedback from my customers makes it all worthwhile.

Until next time. Thanks for reading and hold to the Golden Rule,

Oliver

© 2019 Apitius Mandolins

All Rights Reserved

.

.

RGB.jpg)

(900 X 1125.jpg)